Reasons behind the shortage of new cars in the UK

8 June 2021

From household cleaning equipment to video games and the whole lot in between, everything includes the usage of electronics.

Purchasing any products of electronics has become loathsomely pricey these days. In addition to that, finding and buying such electronics has become almost unmanageable over the last year. It happened mainly because of the significant shortage of the core building block of electronics. This building block is a semiconductor chip (also known as a microchip or simply semiconductor). Other than electronics, they also include all types of vehicles. Over the past few decades, brand new cars have become progressively dependent on electronics as well. The lack of semiconductor chips is leading to the shortage of new vehicles. Perhaps, it is the most distressing supply chain interruption in the automobile industry seen in the past several years (or seen ever, if you ask some administrators).What is a semiconductor chip?

A microchip is a tiny piece of semiconductor that makes an integrated circuit or monolithic integrated circuit. Several electronic devices use semiconductor chips as core parts of their electrical system and circuitry. Some electronic devices include your computer, laptop, cell phone, video games, cars, etc.Why do new cars need semiconductor chips?

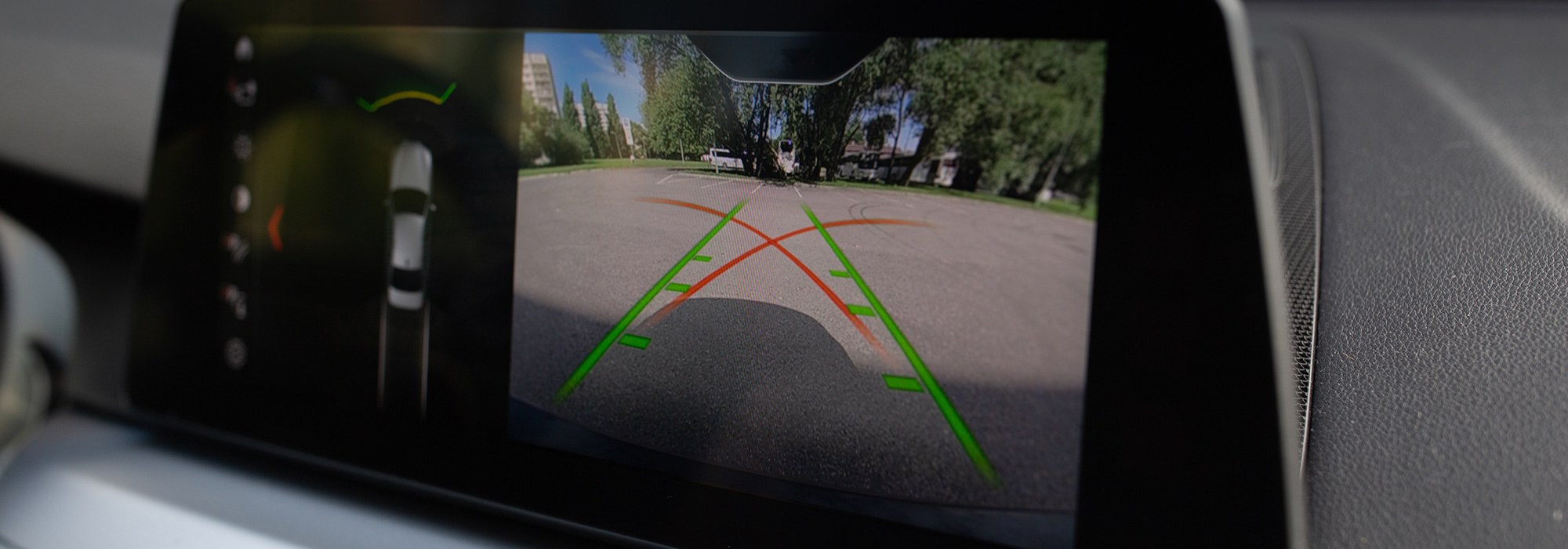

Semiconductor (neither a true conductor nor insulator) makes a fundamental building block in electronics production. Many electronic products use these semiconductor chips due to various reasons. However, in simple terms, they have many designed minute circuits allowing every electronic device to work. The same is the case with brand new cars – they use these chips for almost everything. It includes digital display systems, entertainment system, parking cameras, etc.

Why is there a shortage of semiconductor chips in supply to car manufacturers?

As we know car manufacturers use microchips in a lot of the car’s systems, so even their slight delay can have disastrous effects on the manufacturing and fabrication of such products. In recent times, these delays are happening a lot and transforming into a shortage. Furthermore, it is resulting in massive bottle-neck of vehicle orders. Some of the key reasons behind the shortage of new cars in the UK at the minute are:1. COVID-19

In the past one and a half year, the semiconductor chips global supply chain disrupted due to the COVID-19 issues and complications. Like every other industry, the automobile and chip manufacturing industry also stopped working during the pandemic. The large-scale factories shut their doors due to the government mandate. The excess of caution for employees’ health was another reason for the halt. Ultimately, it caused a backlog in manufacturing along with an increment in the electronics demand. We all know that everyone stopped purchasing new vehicles at the beginning of the global pandemic. Therefore, the orders from the car manufacturers for the semiconductor chips dropped abruptly. At this time, the technology companies were procuring semiconductor chips left, right, and centre. These companies include laptop and cell phone manufacturers. At that time, Sony was the most noticeable firm due to its endless demand for the latest PlayStation 5.2. Factory fire

In addition to the COVID-19, a plant (Renesas) for semiconductor microchips production in Japan caught fire in March. Consequently, it turned out even with more delays in the chip manufacturing as it caused damaged damage to seventeen of its machines. Some news says that semiconductor chip manufacturing at the plant would not initiate again until July (at least).3. Storm

A storm also came in Texas, which setback the allocation of semiconductor chips and hampered its production process even further. The United States produce about 12% of total chips in the whole world, mainly in Texas. A severe storm hit Texas in February, which resulted in the halt of chips’ production and power cuts. It will almost take four months to get back to normal since it was way much catastrophic. Some new cars affected by the semiconductor chip shortage in the UK- Mercedes paused the production of GLC.

- Mazda reduced its manufacturing number by 7,000 cars in the first quarter of 2021.

- Mini closed its Oxford plant that produced 5-door and 3-door hatchbacks.

- Volkswagen manufactured 10,000 less than planned new cars in 2021.

- Toyota suspended manufacturing in two factories in Japan.

- Hyundai halted the production of some SUVs.

- Tesla also got affected by the shortage of microchips.

- Mitsubishi dropped the car manufacturing number by 16,000 in January and February.

- Jaguar Land Rover revised its car manufacturing schedule for two factories in the UK.

- Peugeot, Citroen, Fiat, Vauxhall, Chrysler also slowed down their car production process.